With the brand new version released a few days ago, it’s obvious that new META AM 29 has benefited from many changes both aesthetically and specifically. Each year, the development of each new frame and part passes through the hands of our designer Thomas Moret. He tells us about the part he played in the design of the new META AM 29.

|

|

|

|

C: How long does it take between your first drafts and the production of a prototype? First production models?

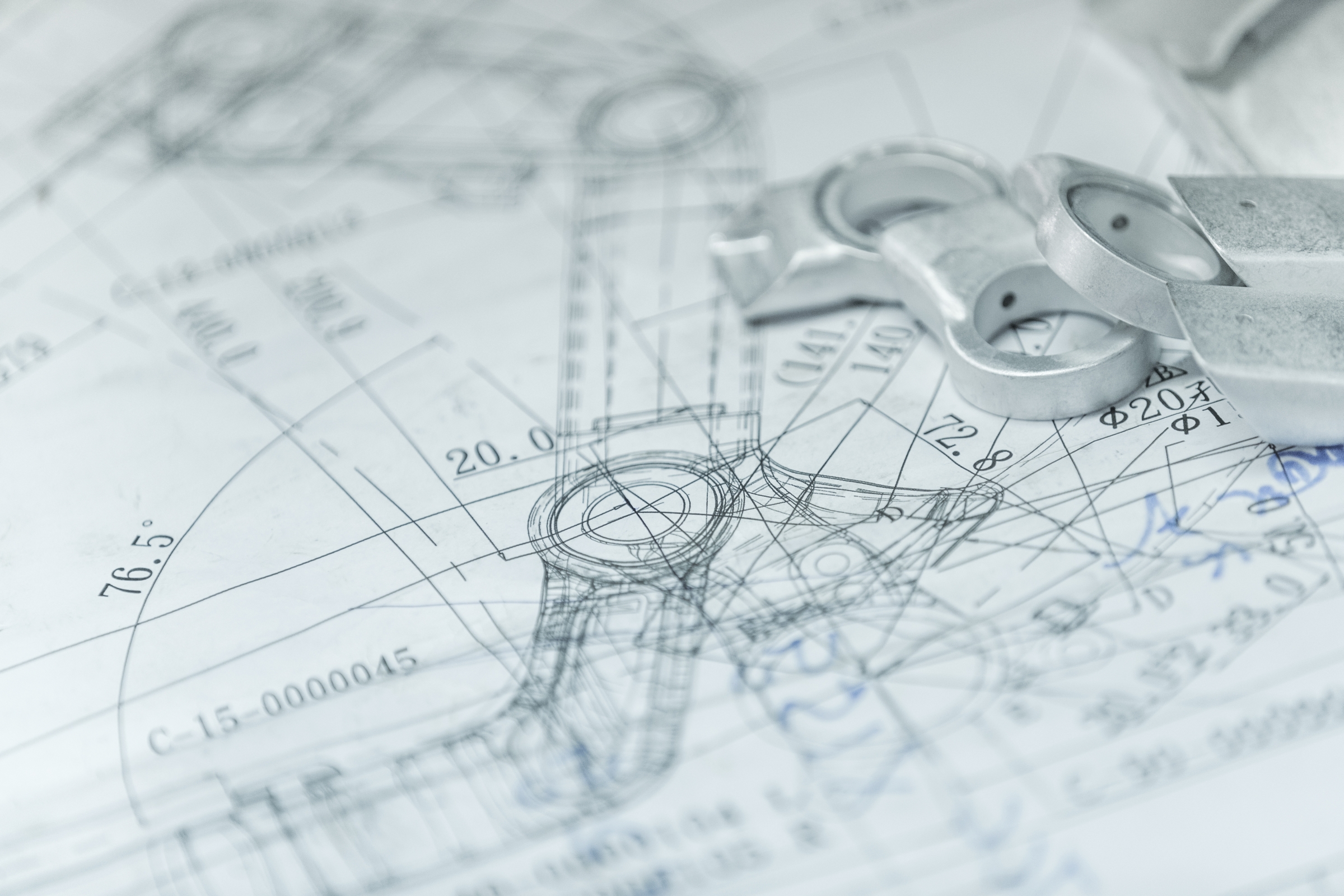

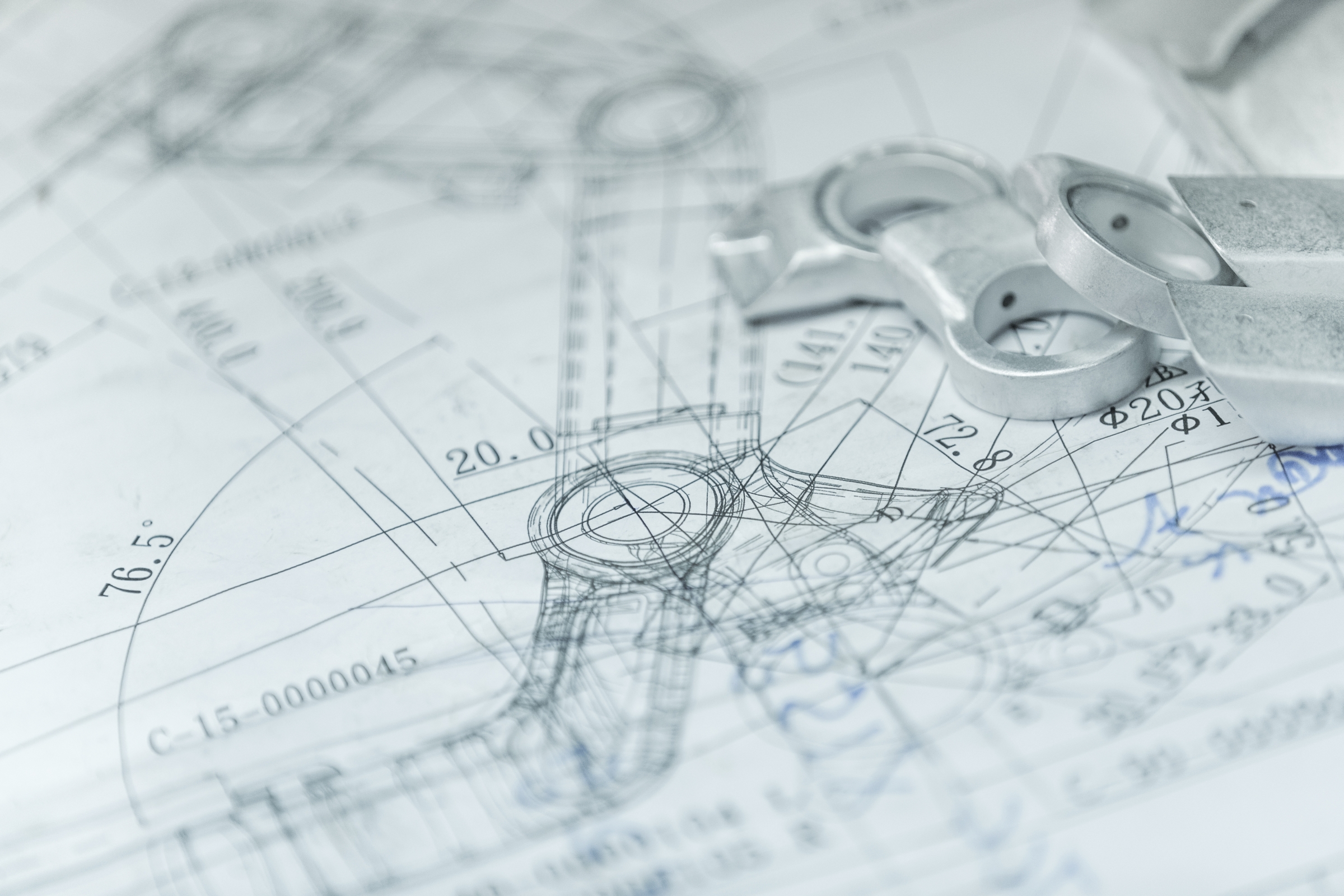

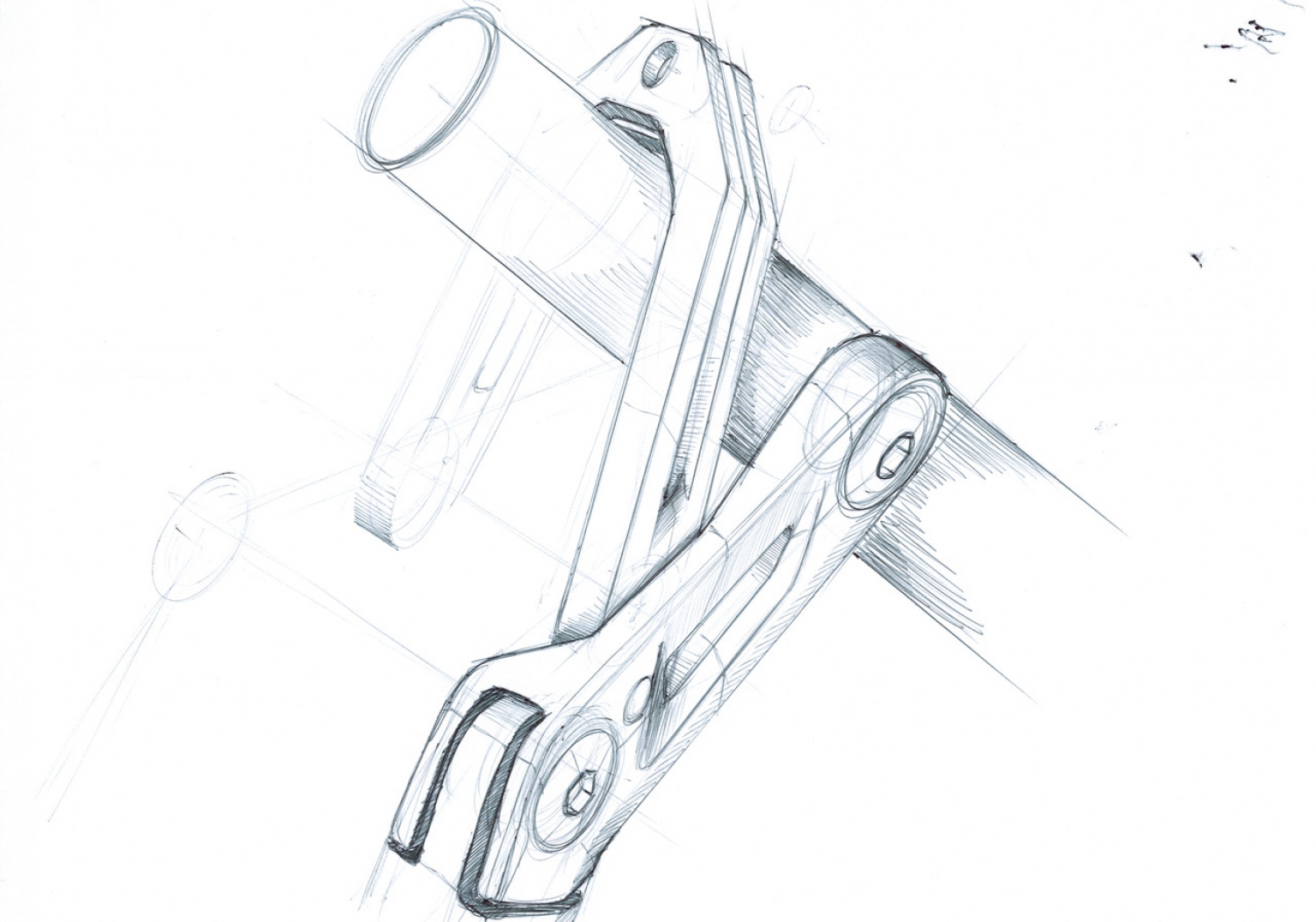

TM: It all depends on the project. On a new platform it can take more than a year between drawings and the first prototypes. On a re-styling like here, in a few months the changes to be made are identified, drawn, modelled, printed and validated for production. Thanks to 3D printing we can now reduce our development times by validating a multitude of points directly from our offices in Andorra!

C: How would you define the aesthetics of this new frame?

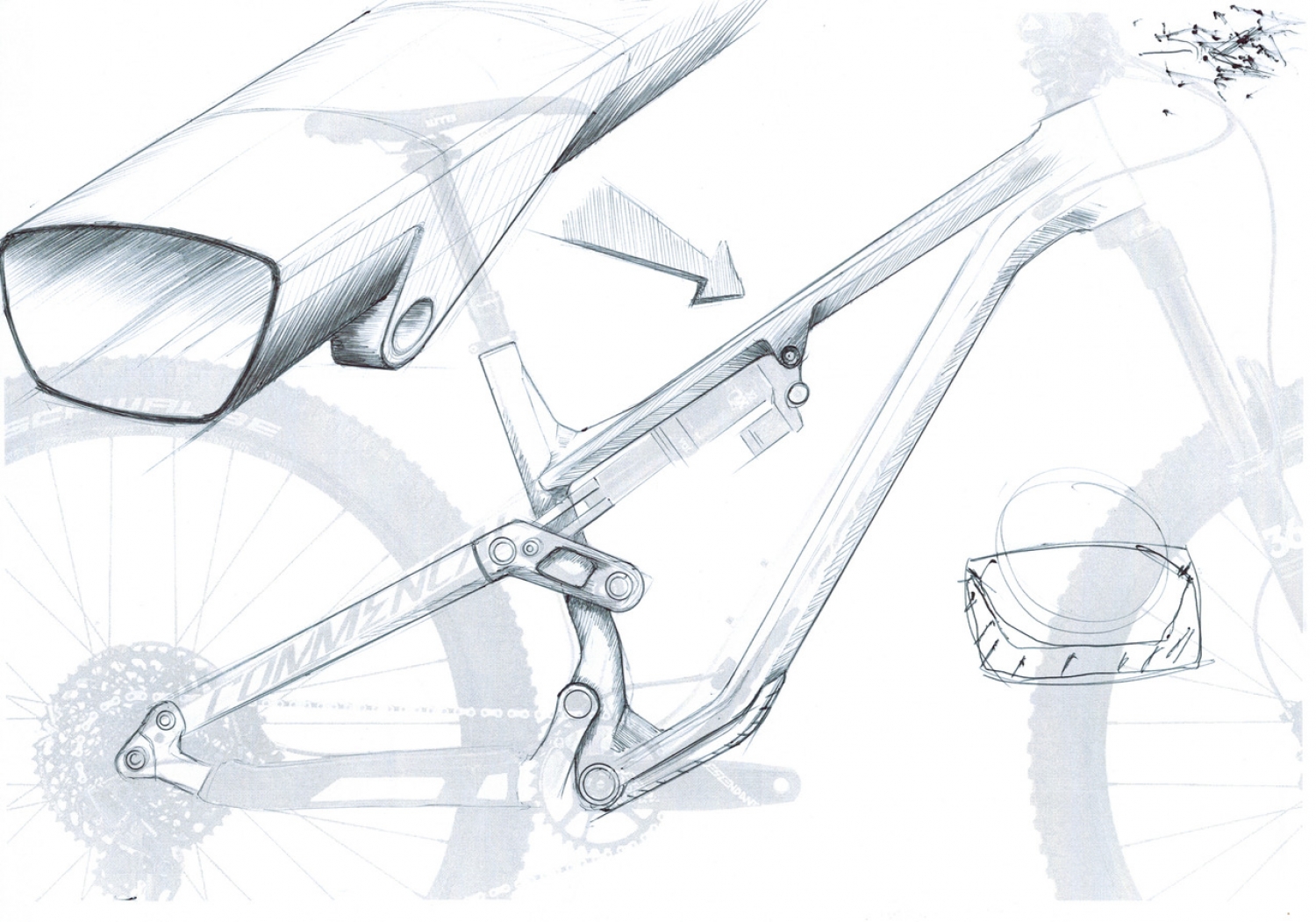

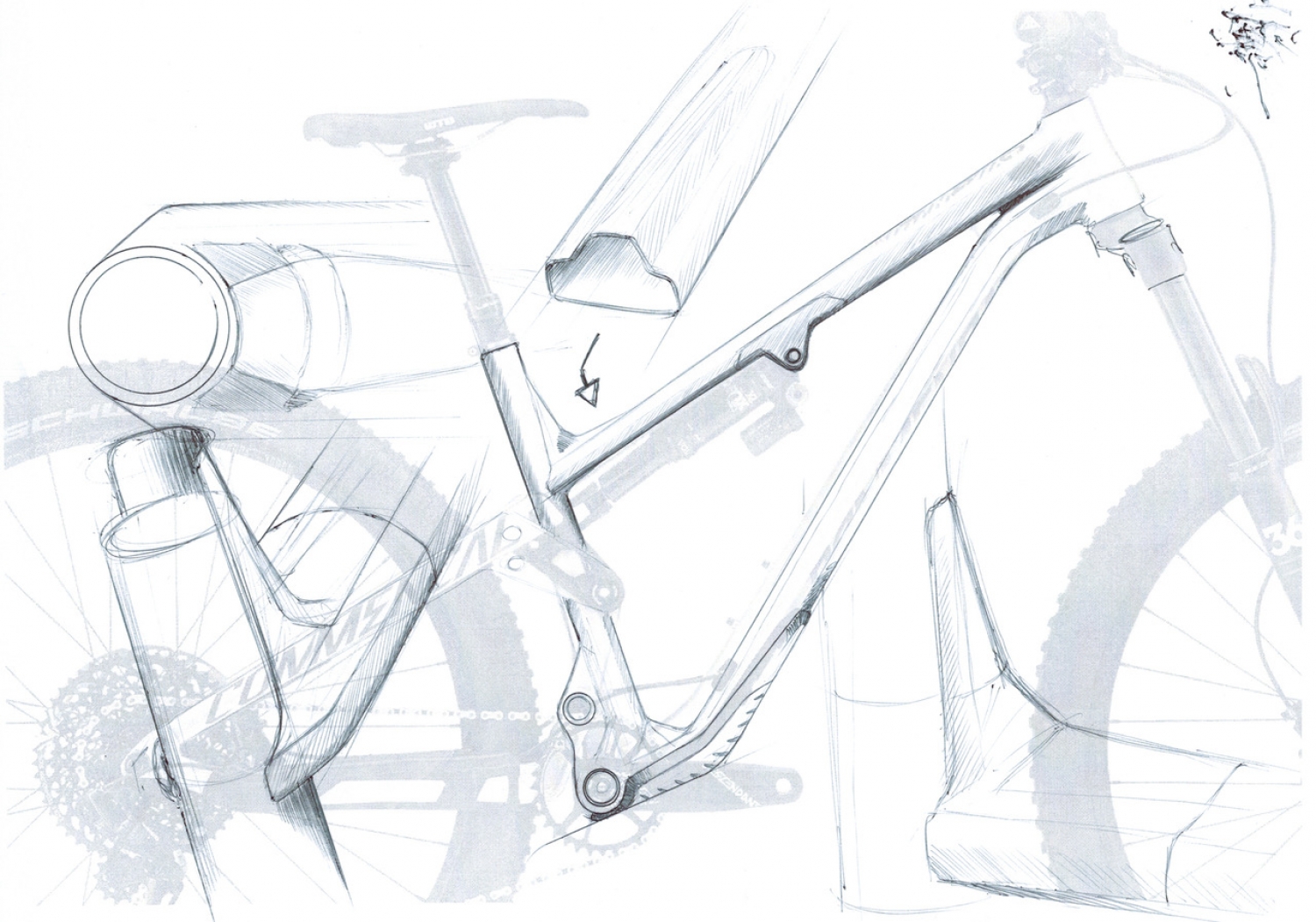

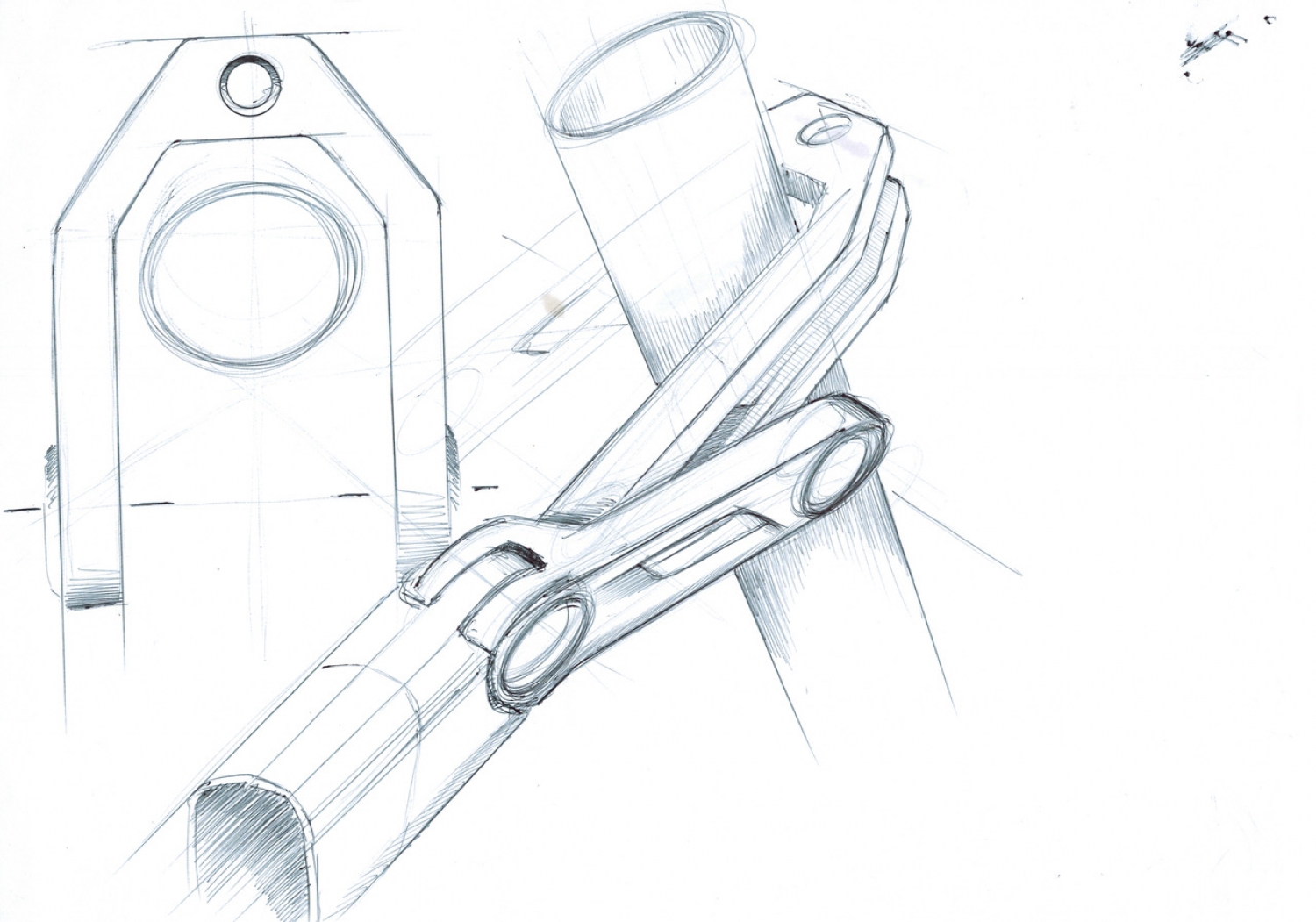

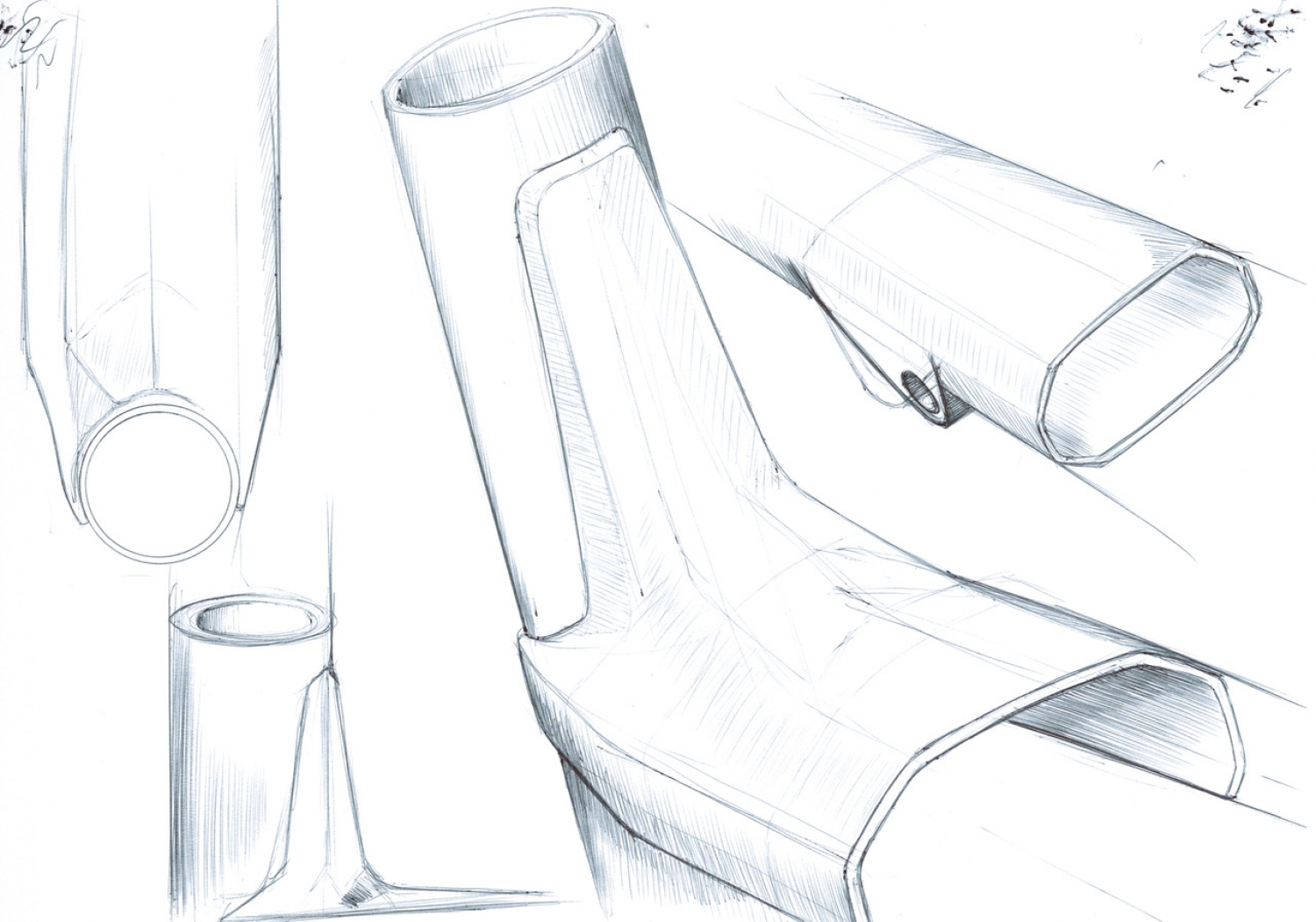

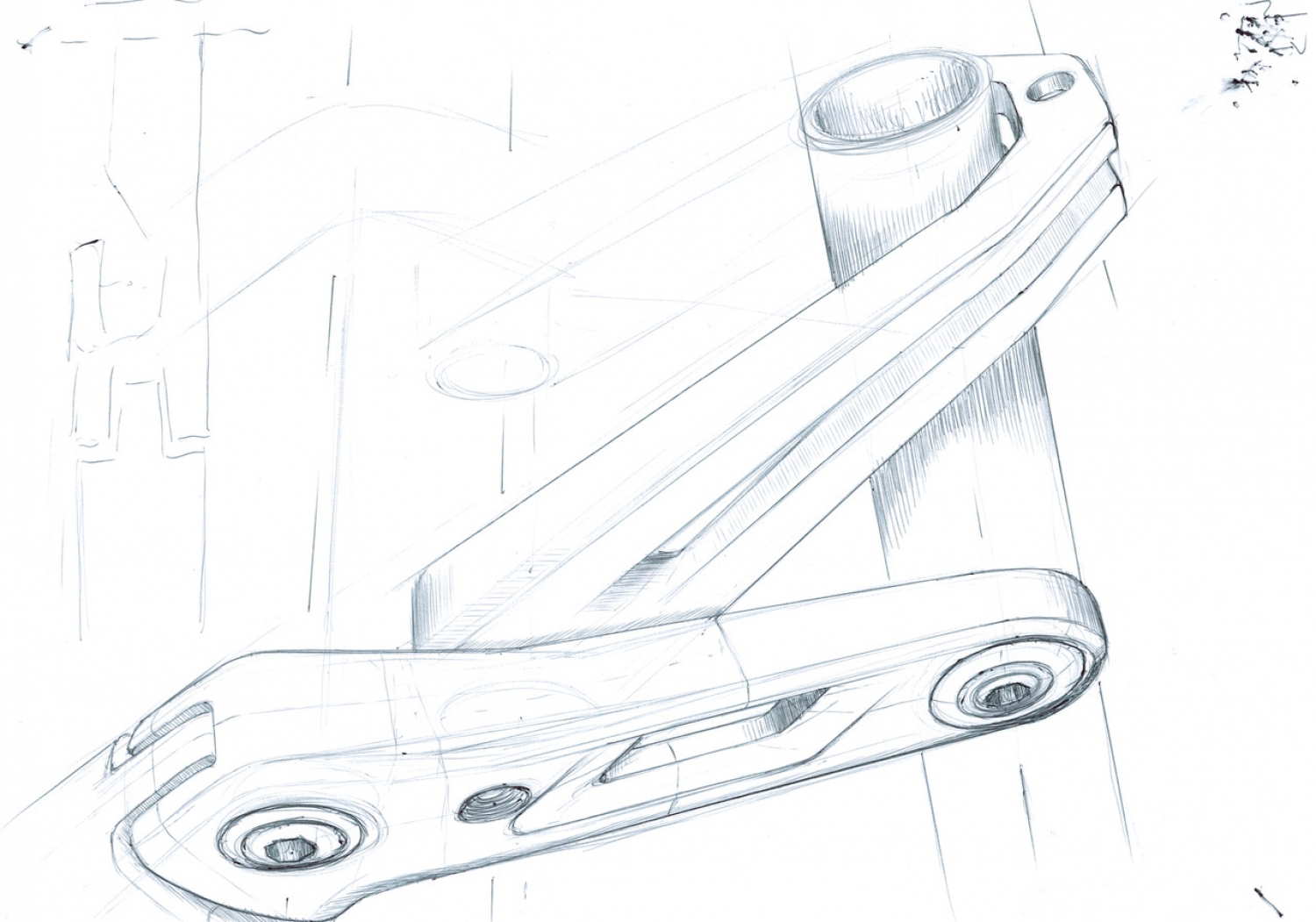

TM: For this new META TR 29 we wanted a more slender line. No more top tube bent upwards to connect to the seat tube. We wanted a lower overall line which gives a more compact look with tighter lines. It's more contemporary and technically, with aluminium, it's less complicated to control through the industrial stages. For mechanical parts such as the tilting linkage called the 'contact system', it had to be resized to meet technical constraints and to have good overall harmony plus a solid and refined visual feel. And one which makes you want to ride!

.jpeg) |

|